Offering soft serve to customers is a delightful way to satisfy their craving for a delicious frozen treat and increase your business profits. Soft serve can be the center of attention as a stand-alone vanilla or chocolate cone or a perfect addition to other dessert options, such as on top of a cake or served with coffee (known as an affogato). Vanilla is a fantastic base, but we are not limited to just that; there are many creative ways to introduce soft serve. It can be mixed with flavour ribbons like Flavor Burst or topped with syrups, cookie crumbles, or sprinkles. The mix you use can be homemade or bought. It can be dairy or dairy alternatives like coconut milk or trending lentil soft serve. It can even be mixed with alcohol or wine. The possibilities for creativity are endless in making this treat unique. Many businesses, ranging from convenience stores to quick-service restaurants, full-service dining, cafes, and food trucks, incorporate soft serve into their offerings, as customers of all ages around the world enjoy this sweet treat. Soft serve is always fresh and creates a moment of joy that makes you smile.

Commercial soft-serve machines offer a high level of customization to cater to various taste preferences, making it the perfect versatile frozen treat option. When choosing the machine, there are two styles on the market today, pump style and gravity style. We will cover the main differences and how they affect the speed of serving the product, consistency, overrun and product waste.

What is the difference between pump and gravity-style machines?

There are two major differences between pump and gravity-style soft serve machines.

Pump-fed soft serve machines introduce additional air into the product by using the internal pressurized pump to push the product into the freezing cylinder, which can have a higher or more consistent overrun.

Gravity-fed soft serve machines use gravity to feed the product mix down the mix feed tube into the freezing cylinder, which typically results in lower overrun than pump-style units.

Pump Style

Pump-style units have a pump in the hopper that pushes the mix into the mix feed tube assembly. Pump units use knife-style scraper blades. The pump and the beater create pressure in the barrel, which moves the product forward to dispense. Pump-style units allow for higher overrun ranging from 25-100%, which is easy to adjust by changing the air diaphragm in the pump. Also, the pump-style machine capacity is higher, allowing you to serve more product that is of consistent quality at a faster rate.

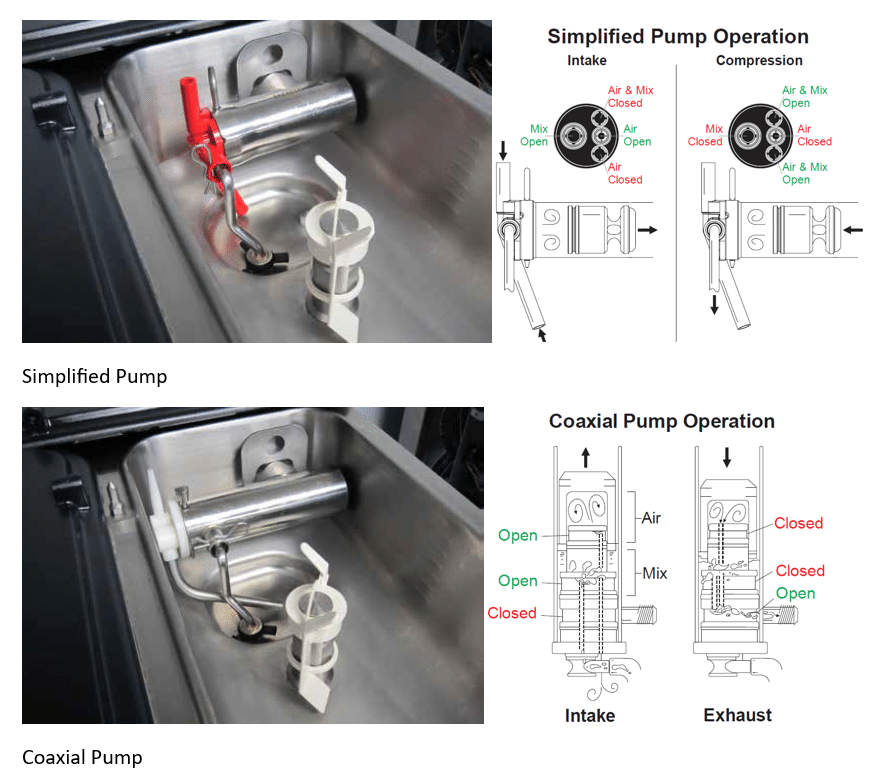

There are two types of hopper pumps, simplified and coaxial. The simplified pump is the newer style and is standard on pump-style units. The coaxial pump is an option chosen if the customer wants to narrow the range of variance in overrun.

When cleaning the unit, the pump will suck up the liquid mix from the hopper and then pump it into the freezing cylinder. The hopper could be nearly empty, and it will still get that mix into the freezing cylinder. Therefore, there is less product waste for your operation.

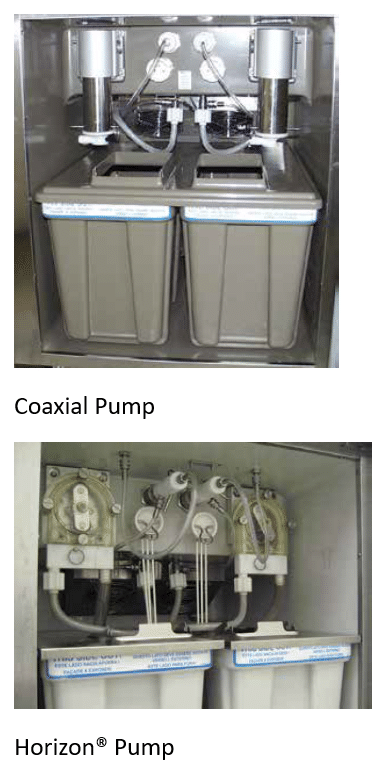

Mix Cabinet Pump Style

Cabinet-style units store the mix in a lower compartment, pump the mix up to the hopper, and offer high storage capacity. There are two types of pumps for the mix cabinet style units, coaxial and Horizon® (peristaltic). The coaxial pump is standard on cabinet-style machines. The Horizon® pump is an option and offers more adjustable overrun.

Gravity Style

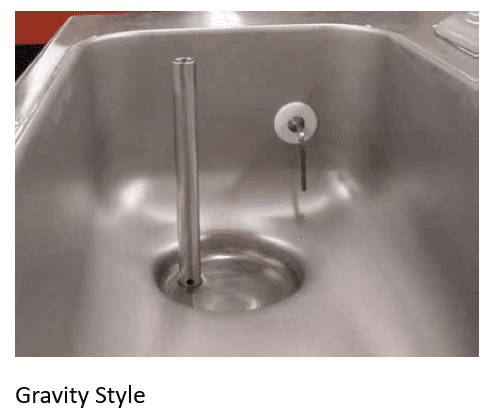

There is a hopper at the top of the unit where the mix is poured in. Gravity feeds the mix into the freezing cylinder as it flows down the mix feed tube. Gravity-style units use shoe-style scraper blades in the barrel to auger the product forward to dispense and typically have lower overrun than pump-style units. The overrun can be modified by selecting the preferred diameter of the tube hole. The product in gravity style can be less consistent. The capacity for serving the product is less than pump-style units.

When cleaning the unit, there needs to be enough product in the hopper to “push” the liquid mix into the freezing cylinder. So, on cleaning days, they might have an inch of product in the hopper that doesn’t get used. Therefore, due to this, there can be a higher amount of product waste.

What is a Mix Feed Tube, and what does it do?

There are 13 different sizing options for mix feed tubes, each with varying diameter hole sizes (located at the bottom side of the tube) between 3.2 mm and 12.7 mm. The appropriate feed tube size depends on the desired amount of overrun.

What is overrun? Read more here, https://www.dslinc.com/the-best-way-to-calculate-ice-cream-overrun/

In conclusion, the primary considerations in deciding which style machine is more suitable for your business are,

Pump Style machines have a higher overrun that is easier to adjust. The overrun ranges anywhere between 25%-100%. This machine style can serve more consistent quality product at a faster pace. The finished product has a lighter texture. These machines are more expensive due to more parts required for the pump.

Gravity-style machines have lower overrun, typically 25-35% (adjusted by selecting the mix feed tube hole diameter size), and the finished product has a denser texture. This machine can serve a quality product which may be less consistent and at a slower pace than its counterpart. There can be a higher amount of product wastage due to the nature of gravity. This machine is less expensive because it requires fewer components. Generally, people looking to serve a more gourmet product choose gravity-style.